Services

24/7 Mobile Welding

We offer 24/7 mobile welding services and same day repairs depending on the depth of the project.

Mobile welding services bring their equipment and expertise to the client’s location. This eliminates the need to transport heavy or bulky items to a welding shop, making it a convenient option for on-site repairs or projects.

Plasma Cutting

We offer plasma cutting for all your construction, manufacturing, industrial, commercial, and residential needs.

Plasma cutting is a widely used and versatile method for cutting various materials, primarily metals, with high precision and efficiency. It is commonly used in industries such as metal fabrication, automotive, construction, and manufacturing. Plasma cutting involves creating an electrically conductive plasma arc that is used to melt and cut through the material being processed. The basic components of a plasma cutting system include a power supply, a torch, and a gas supply.

In summary, plasma cutting is a versatile and efficient method for cutting metals and other materials, offering precision, speed, and a range of thickness capabilities. It is widely used in various industries where accurate and fast cutting is required.

Handrails, Ladders, and Platforms

We install and fabricate new hand rails along with ADA compliance. We modify and repair existing handrails of all materials and have the capability to do so on site. We can take care of core drilling and anchoring as well.

Whether in residential, commercial, or industrial settings, handrails, ladders, and platforms play crucial roles in enhancing safety, providing access, and facilitating various activities. Proper design, construction, and maintenance are essential to ensure these components function effectively and meet safety standards.

Installing / Setting Heavy Equipment and Machinery

We have the knowledge and capabilities to properly and precisely set all your heavy machinery and equipment. We coordinate and plan the layout according to the clients requirements and prints, using proper rigging techniques and equipment to carefully and precisely install whatever you need (conveyors, industrial / mechanical equipment, manufacturing equipment and much more).

Installing and setting up heavy equipment and machinery is a complex and crucial process that requires careful planning, coordination, and adherence to safety protocols. Whether you are setting up heavy machinery in a manufacturing facility, construction site, or any other industrial environment. Use appropriate rigging equipment, such as slings, chains, or cables, to securely attach the machinery for lifting and positioning. Installing and setting up heavy equipment and machinery is a complex task that requires expertise, careful planning, and a commitment to safety. It’s essential to involve experienced professionals and follow best practices to ensure a successful installation process.

Tank and Container Builds & Repairs

Tank and container builds and repairs refer to the construction, maintenance, and refurbishment of various types of tanks and containers used for the storage and transportation of liquids, gases, or bulk materials. These tanks and containers serve a wide range of industries, including oil and gas, chemical, food and beverage, pharmaceuticals, and more.

Tank and container builds and repairs are critical for industries that rely on the safe and efficient storage and transportation of various materials. Proper construction, maintenance, and adherence to safety and environmental standards are essential to ensure the integrity and reliability of these vessels.

On Site Repairs

On-site repairs refer to the process of fixing or servicing equipment, machinery, structures, or systems at the location where they are installed or in use, rather than removing them and transporting them to a repair facility. On-site repairs offer several advantages, including reduced downtime, cost savings, and convenience. On-site repair technicians typically bring specialized tools, equipment, and spare parts to the location where the repair is needed. These tools are selected based on the specific repair requirements. On-site repairs are crucial for minimizing downtime, maintaining operational continuity, and addressing issues promptly. They are especially valuable in industries where the cost of downtime is high, such as manufacturing, construction, and utilities. Skilled technicians who specialize in on-site repairs play a vital role in ensuring that equipment and systems remain operational and efficient.

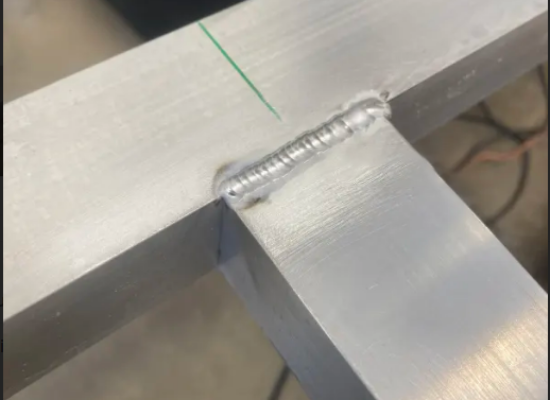

Aluminum Welding & Fabrication

We offer aluminum welding and fabrication and mobile repairs.

Aluminum welding and fabrication require a combination of skill, equipment, and knowledge of aluminum properties and alloys. The specific techniques and processes used will depend on the project’s requirements, material thickness, and intended use of the finished product.

Aluminum welding and fabrication refer to the processes involved in joining and shaping aluminum materials for various applications. Aluminum is a lightweight and corrosion-resistant metal that is commonly used in a wide range of industries, including automotive, aerospace, construction, and manufacturing. Welding and fabrication are essential techniques for creating aluminum structures, components, and product.

Aluminum welding and fabrication require a combination of skill, equipment, and knowledge of aluminum properties and alloys. The specific techniques and processes used will depend on the project’s requirements, material thickness, and intended use of the finished product.

RTUs (roof top units)

If you need any type of RTU for HVAC or any other application , we have the capability to come onsite and perform the welding cutting and laying out as needed for the install.

RTUs, or Roof-Top Units, are HVAC (Heating, Ventilation, and Air Conditioning) systems that are commonly used in commercial and industrial buildings to provide climate control. As the name suggests, these units are typically installed on the rooftop of a building, although they can also be placed on the ground or on a platform near the building. RTUs are known for their efficiency, ease of installation, and space-saving advantages.

RTUs, or Roof-Top Units, are HVAC (Heating, Ventilation, and Air Conditioning) systems that are commonly used in commercial and industrial buildings to provide climate control. As the name suggests, these units are typically installed on the rooftop of a building, although they can also be placed on the ground or on a platform near the building. RTUs are known for their efficiency, ease of installation, and space-saving advantages.

In summary, Roof-Top Units (RTUs) are versatile HVAC systems commonly used in commercial and industrial buildings to provide heating, cooling, and ventilation. They offer several advantages in terms of space efficiency, ease of installation, and energy efficiency, making them a popular choice for climate control in a wide range of applications.

Oxy Acetylene Cutting & Arc Gouging

We offer on site oxy acetylene cutting and arc gouging for a large array of applications. We specialize in cutting and welding thick gauge steel with safety, speed, and efficiency.

Oxy-acetylene cutting and arc gouging are two distinct metal cutting and gouging processes used in metal fabrication, construction, and maintenance industries. They both involve the use of high-temperature heat sources to remove metal, but they differ in terms of the equipment and techniques employed.

Both oxy-acetylene cutting and arc gouging are valuable techniques in metalworking and metal fabrication, and their choice depends on the specific requirements of the task, the type of metal being worked on, and other factors like portability and speed of material removal. Proper training and safety precautions are essential when using either of these methods due to the high temperatures involved.